Call Us

+971544872626

+971544872626

We are now the world leaders and emerging as the world no. 1 company globally in the fabrication and manufacturing of oxygen nitrogen plants along with perfect combination of OEM factories in China, India and Europe and warehouse in JEBEL ALI free zone. Our company has advantage of supplying high quality oxygen nitrogen plants with a perfect blend of design engineering quality control exposure of a first world country using high European and American standards for supply to UAE. Our engineering team and quality control team ensure that the OEM factory in china and India used the best quality standards for manufacturing air separation plants.

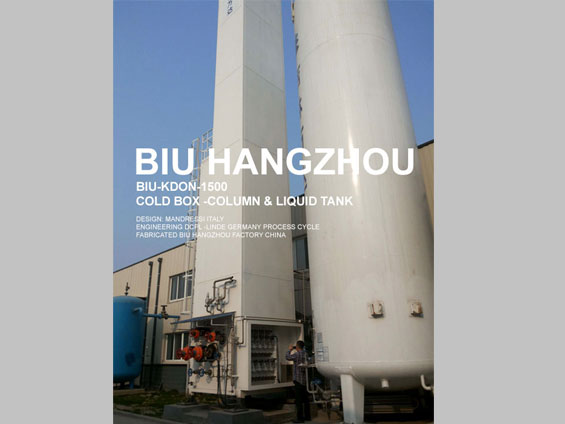

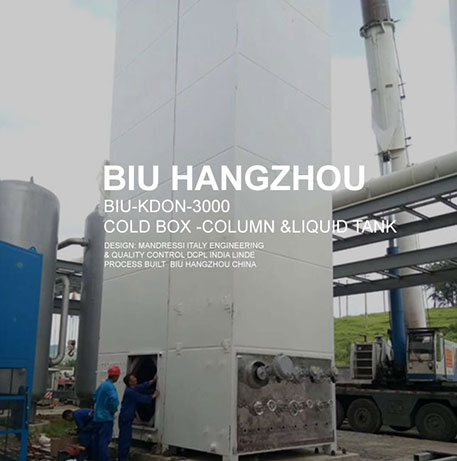

Design & technology will be based on European designs on LINDE German process cycle. Each and every drawing process flow and detailed engineering is precisely done by Cryogenic experts in India & UAE having over 30 years work and manufacturing experience in USA, Europe India and China. All designing team is in-house collaboration with Delhi Cryogenic products and Team of B I plant project management Dubai UAE team with exposure to all Linde process &European designs and safety rules and procedures.

The complete manufacturing of the plants shall be done by OEM factory in Hangzhou company China & Delhi Oxygen factory New Delhi, India depending upon the model and capacity and critical components can be outsourced as per buyer requirements to European companies like Atlas Copco, Schneider, Siemens, Cryostar France, CESA France, Honey Well USA brand, etc, as clearly specified in the offer model-wise.

Used for filling oxygen, nitrogen gas cylinder for Industrial supply to industries for steel fabrication and cutting Column will be fabricated in Aluminum material can be used.

For Medical & hospital supply only plants will be type A European quality column manufactured in stainless steel with the highest quality standards to ensure proper quality of medical oxygen from the oxygen plant. For steel plants, glass manufacturing, Oil & gas refineries, oil wells purging, metals, process industries food and beverage and pharmaceutical industries.

This technology is considered the best option for generating oxygen with 99.7% purity for medical and 99.5% % to 99.6% for industrial and nitrogen with 99.9999% purity. Our plant will allow our clients to generate oxygen & nitrogen in both liquid and gaseous form. All factories are certified with ISO 9001:2015 and CE standards. Our plant is reliable, durable and highly efficient.

"WE COMPLY With THE HIGHEST QUALITY STANDARDS IN THE AIR SEPARATION INDUSTRY AS PER BUYER REQUIREMENTS AND MODEL"

| Type Parameters | Oxygen Output NM3/Hr | Oxygen Purity %02 | Gas Oxygen Pressure Mpa | Nitrogen Output NM3/Hr | Nitrogen Purity %/ppm02 | GAS Nitrogen Pressure OUT OF COLD BOX Mpa |

|---|---|---|---|---|---|---|

| BI-KDON 600/1500 | 600 | 99.6 | 0.04 Mpa | 1500 | 99.99 To 3ppm | 0.5Mpa |

| BI-KDON 1000/2500 | 1000 | 99.6 | 0.04 Mpa | 2500 | 99.99 To 3ppm | 0.5Mpa |

| BI-KDON -1500/3750 | 1500 | 99.6 | 0.04 Mpa | 3750 | 99.99 To 3ppm | 0.5Mpa |

| BI-KDON -2000/5000 | 2000 | 99.6 | 0.04 Mpa | 5000 | 99.99 To 3ppm | 0.5Mpa |

| BI-KDON -3000/5000 | 3000 | 99.6 | 0.04 Mpa | 5000 | 99.99 To 3ppm | 0.5Mpa |

| MODEL | LIQUID OXYGEN (NM3/HR) | Kg /hour (tons per day tpd) | OXYGEN PURITY (%) | Liquid oxygen Pressure Mpa |

|---|---|---|---|---|

| BI-KDO-500Y | 500 | 668(16) | 99.7 | 0.04 Mpa |

| BI-KDO-1000Y | 1000 | 1336(32) | 99.7 | 0.04 Mpa |

| BI-KDO-1500Y | 1500 | 2000(48) | 99.7 | 0.04 Mpa |

| BI-KDO-2000Y | 2000 | 2672(64) | 99.7 | 0.04 Mpa |

| BI-KDO-3000Y | 3000 | 4000(96) | 99.7 | 0.04 Mpa |

| MODEL | LIQUID NITROGEN (NM3/HR) | Kg /hour (tons per day) | NITROGEN PURITY (%) | Liquid nitrogen Pressure Mpa |

|---|---|---|---|---|

| BI-KDN-500Y | 500 | 585(14) | 99.99 To 3ppm | 0.5Mpa |

| BI-KDN-1000Y | 1000 | 1170(28) | 99.99 To 3ppm | 0.5Mpa |

| BI-KDN-1500Y | 1500 | 1755(42) | 99.99 To 3ppm | 0.5Mpa |

| BI-KDN-2000Y | 2000 | 2340(56) | 99.99 To 3ppm | 0.5Mpa |

| BI-KDN-3000Y | 3000 | 3510(84) | 99.99 To 3ppm | 0.5Mpa |

| MODEL | GAS NITROGEN (NM3/HR) | NITROGEN PURITY (%) | Liquid nitrogen Pressure Mpa |

|---|---|---|---|

| BI-KDN-500 | 500 | 99.99 To 3ppm | 0.5Mpa |

| BI-KDN-1000 | 1000 | 99.99 To 3ppm | 0.5Mpa |

| BI-KDN-1500 | 1500 | 99.99 To 3ppm | 0.5Mpa |

| BI-KDN-2000 | 2000 | 99.99 To 3ppm | 0.5Mpa |

| BI-KDN-3000 | 3000 | 99.99 To 3ppm | 0.5Mpa |